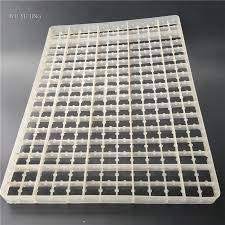

A hatchery tray is a specialized tray used in poultry hatcheries to incubate and hatch eggs. These trays are designed to provide a controlled and safe environment for the eggs during the incubation period. Here are some features of hatchery trays:

- Size and capacity: Hatchery trays are available in different sizes and capacities to accommodate different types of eggs and hatchery needs. Some trays are designed to hold as few as 30 eggs, while others can hold hundreds or even thousands of eggs.

- Material: Hatchery trays are typically made of durable and lightweight materials such as plastic or aluminum. This allows for easy handling and cleaning, as well as durability over many hatching cycles.

- Ventilation: Hatchery trays are designed to provide adequate ventilation to the developing embryos. This is typically achieved through the use of ventilation holes or slots in the tray, which allow for the exchange of oxygen and carbon dioxide.

- Egg positioning: The eggs are carefully placed in the tray with the larger end up, to ensure that the air cell is located at the top of the egg during incubation.

- Turning mechanism: Many hatchery trays are designed with a mechanism that allows for automatic turning of the eggs. This helps to ensure even heat distribution and proper development of the embryos.

- Water channels: Some hatchery trays have channels that allow for water to be added, which can help to maintain the proper humidity levels during incubation.

- Labeling: Hatchery trays are often labeled with information about the breed, date of incubation, and other relevant information to help ensure proper tracking and management of the eggs.

Hatchery trays are an essential component of modern poultry hatcheries and play a critical role in ensuring the safe and efficient incubation of eggs.